Freeze-drying technique

The history

The freeze-drying process, also called a lyophilisation process, is the most advanced and nutrient-safe drying technology in the world. The process is based on the removal of water from a frozen product by sublimation of ice. This means that the ice turns directly into water vapour, omitting the liquid state. The vacuum makes sublimation possible under low temperature, so freeze-dried food preserves its aroma, taste, shape, texture, colour, flavour and nutrient content – with no additives!

Freeze-dried food retain about 95% nutritional and biological value of the fresh product.

Freeze-drying technology was invented around 1900. At the beginning, it was implemented for medical purposes only. Thanks to the ability to preserve heat-sensitive biological materials, the freeze-drying technique was used to preserve blood serum.

Besides the pharmaceutical industry, the freeze-drying technology started being used as a method of preparing food for soldiers and astronauts in the mid-1900s. Since then, freeze-drying technology has been a focal point of food preparation for space travel.

Freeze-dried food developed by NASA for astronauts

NASA funded research on a variety of possible food preservation methods, including dehydration, intermediate moisture, nitrogen packing, pasteurization by irradiation, and freeze-drying. According to the research, the most effective technique was freeze-drying as it preserved the most nutritional content and extended shelf life. NASA also found that freeze-dried meals are easier to rehydrate for astronauts. Moreover, freeze-dried food is lightweight which is very important in space travel.

NASA Apollo and Gemini Project missions

Freeze-dried food was first introduced during the famous NASA Gemini Project missions, and during the Apollo missions already most foods for astronauts was freeze-dried. Just before packaging, fresh food was quick-frozen and then put into a vacuum chamber. The vacuum air removed virtually all moisture from the food. It was packaged while still being in the vacuum chamber.

Some of these space meals, for instance, the brownie cubes and cereal, could be eaten without any preparation. The other meals required adding cold or hot water through the tube which was a part of the packaging (hot water was available starting from the Apollo missions only). Just after rehydration, the freeze-dried meal was squeezed into the astronaut’s mouth through the nozzle in the package.

Emergency food supply kit

On Earth, freeze-dried food first started to be very popular with military forces and also backpackers and hikers. Moreover, many people who have limited access to food and power supply, especially those living in regions prone to natural disasters (e.g., fires, earthquakes, hurricanes, etc), use freeze-dried products as part of their emergency food supply kit.

Guilt-free food for taste!

Nowadays, freeze-dried food is widely available and affordable for almost everyone. Freeze-dried components are used in so many pre-made products, for instance, granolas, cereals, chocolates, instant soups, shakes and coffees, natural food colouring and flavouring, pet foods, packed lunch, ready to eat meals, backpacking meals and standalone snacks (e.g., freeze-dried fruits).

Now available for everyone

Try it yourself!

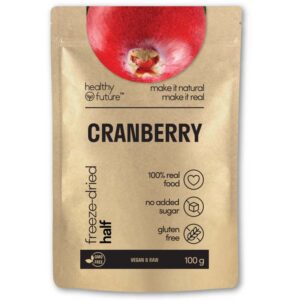

Our freeze-dried herbs, vegetables and fruits are 100% natural, vegan and raw, gluten-free, GMO-free, with no added sugar or sulphur, with no preservatives. Moreover, they are incredibly light and portable, crunchy, firm and easy to store.

Freeze-dried fruits, vegetables and herbs are a great alternative when the season for our favourite fresh products is over – they are available all year round!

Check our offer of freeze-dried fruit, vegetables and herbs in powdered form as well as crunchy pieces of your favourite ones!

Freeze dried vs dried

Freeze dried fruits

- About 95% of the nutritional value of fresh fruit (vitamins, minerals, antioxidants) is retained.

- No added sugar - only contain naturally occurring sugars.

- No added sulphur and preservatives.

- No added oil.

- Natural look, taste, texture, colour and aroma is retained without any artificial additives, preservatives, flavour and colour enhancers.

- When kept in a cool, dry place (in tightly closed packaging) can be stored for years.

- Water-free – resistant to the development of mould, bacteria and fungi.

- Incredibly light, portable and compact.

- Crunchy and firm - looks great during meals.

- Can be rehydrated very quickly and easily.

- More friendly for people suffering from allergies and food intolerances (no added artificial additives).

Dried fruits

- Only about 20% of the nutritional value of fresh fruit is retained (vitamins, minerals, antioxidants are almost lost).

- Sugar is often used as an additive.

- Most contain added sulphur and preservatives.

- Oil is often added to prevent from sticking together and providing a preserved look.

- Artificial additives are very often added to maintain the colour, taste and aroma (e.g. preservatives, sulphur, oil, sugar).

- Shorter shelf life – deteriorates faster.

- Water content up to 30-40% – promotes deterioration (growth of bacteria, fungi and mould).

- More dense and less compact.

- Soft and misshapen – will not look appetizing.

- Need at least a few hours to be rehydrated.

- Less friendly for people suffering from allergies and food intolerances (artificial additives are usually added).

Freeze dried fruits, herbs & veggies

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

Guilt-free food for taste!

What is freeze-dried food?

The word ‘freeze-dried’ is not very well known yet. Despite the foreign-sounding name, freeze-dried food is 100% natural – with no preservatives, no colour or flavour enhancers, no added sugar or sulphur. It is nothing more than the essence of the food. The only thing that is removed from the product is water.

Freeze-dried products are raw and highly rich in nutrients as material intended for freeze-drying (fresh fruits, vegetables and herbs) is processed when it is naturally fully ripened, there is no need to store or stop its growth.

Moreover, the freeze-drying process takes place at a low temperature and under significantly reduced pressure. Keeping the temperature low enough during the whole process, protects the nutritional values and cell structure of the original material.

These are the reasons why the freeze-drying technique enables retention of around 95% of nutrients (vitamins, minerals, antioxidants) from fresh and ripe products.

As a result of this dehydration process, the final product sometimes loses even more than 90% of its original weight. Thanks to the reduced moisture content, up to 2%, the shelf life of freeze-dried vegetables, herbs and fruits is much longer than the fresh produce. It also allows for easier transportation and storage.

The most popular freeze-dried products are fruits, vegetables and herbs. You can enjoy them not only during the warmer months, but all year round.

What is freeze-drying process?

Freeze-drying is the best dehydrating and drying technique for heat-sensitive products. The fundamental rule of freeze-drying technology relates to the sublimation process (a transition from a solid to a gas phase without entering a liquid phase).

The freeze dryer creates a vacuum environment in the chamber, which allows to lower the air pressure and initiate the sublimation phase. During the freeze-drying process moisture, up to 99%, is removed from the material. The whole process is being carried out under low temperature and low air pressure.

Ice crystals change into gaseous directly, without melting which has a significant meaning for preventing the shrivelled and mushy appearance in the final product. This is the reason why the freeze-dried product looks like a fresh product and without a mushy appearance.

Important! Even the best freeze-drying process and the best quality raw material do not guarantee the freshness of the freeze-dried products if they are not stored in suitable bags or containers. Below, you can find more information about how to store freeze-dried products and which packaging is the best to protect them.

4 stages of freeze-drying process

Selecting

Only fresh and top-quality raw materials are selected – harvested at the peak of their nutritional perfection and ripeness, from trusted suppliers and contracted farmers.

Freezing

To preserve a texture and nutritive content, the freezing is done rapidly, utilizing temperatures ranging from -50 to -80° C.

Drying

Inside of the frozen raw product, ice molecules sublime, i.e., change directly from their solid ice form into a water vapour, omitting a melting phase. The material gently and slowly dries under low temperatures. This process takes several hours.

Packaging

Sealed in airtight packaging to stay crunchy, fresh, and nutrient-rich – no preservatives needed.

How to store freeze-dried products?

Why the packaging is so important?

The best packaging for freeze-dried food

Freeze-dried products are highly hygroscopic. They absorb moisture from the environment. Therefore, they should not be stored in an open container, close to high humidity (e.g. food being cooked) as they will form a mass. Moreover, freeze-dried food is sensitive to light so it should be protected by a suitable non-transparent package or storage in a cupboard.

These are the main reasons why top-quality, tightly closed packaging is important. Our freeze-dried products are packed in strong, durable, non-transparent and high-barrier stand-up pouches with zip locks, giving the content inside the best protection against humidity, oxygen, daylight, heat and foreign odours.

It helps to keep the product fresh and preserve its high quality (including colour, flavour, and health benefits). If suitably packed, freeze-dried products can be stored for a long time.

Reduce waste, save food and the planet

Did you know that every year around 1.3 billion tonnes of food produce is wasted worldwide? including as much as 45% of all vegetables and fruits production. According to statistics this stands for 120 kg of vegetables and fruits wasted by consumers per capita every year.

Freeze-dried food helps to reduce the wasting of food as it can be stored for a long time without spoilage. The low moisture content inhibits enzymes and microorganisms, which makes it long-lasting. In hermetic packaging, even without refrigeration, these products are fresh and tasty for many years.

Moreover, raw material intended for lyophilization is not peeled so the food is eaten with the skin. On top of that, freeze-dried products are often chosen by customers as they look always appetizing!

Feel free to browse and enjoy our lyophilized treats

Orders over £30

100% secure

Just try it!

Always ready to help